Arkansas Plant: Precision Cabling, Peak Performance, USA

Frequently overlooked, the Intermediate Distribution Frame (IDF) functions as the essential hub for localized network segments. At a prominent food and beverage facility in Arkansas, USA, their overcrowded, inefficient, and poorly managed IDFs emerged as the chief bottleneck drastically limiting throughput and triggering a ripple effect of instability throughout their production network.

Our wired infrastructure survey peeled back the layers of this challenge, revealing extensive cabling congestion, inconsistent labeling, and a critical lack of proper cable management across multiple key locations. In an environment where both vital IT (Information Technology) and precision OT (Operational Technology) systems churn around the clock, even a fleeting connectivity hiccup had the chilling potential to grind the entire production line to a halt. The mandate was clear, yet daunting: to completely redesign, strategically relocate, and meticulously restore order; all without skipping a beat in their continuous production schedule.

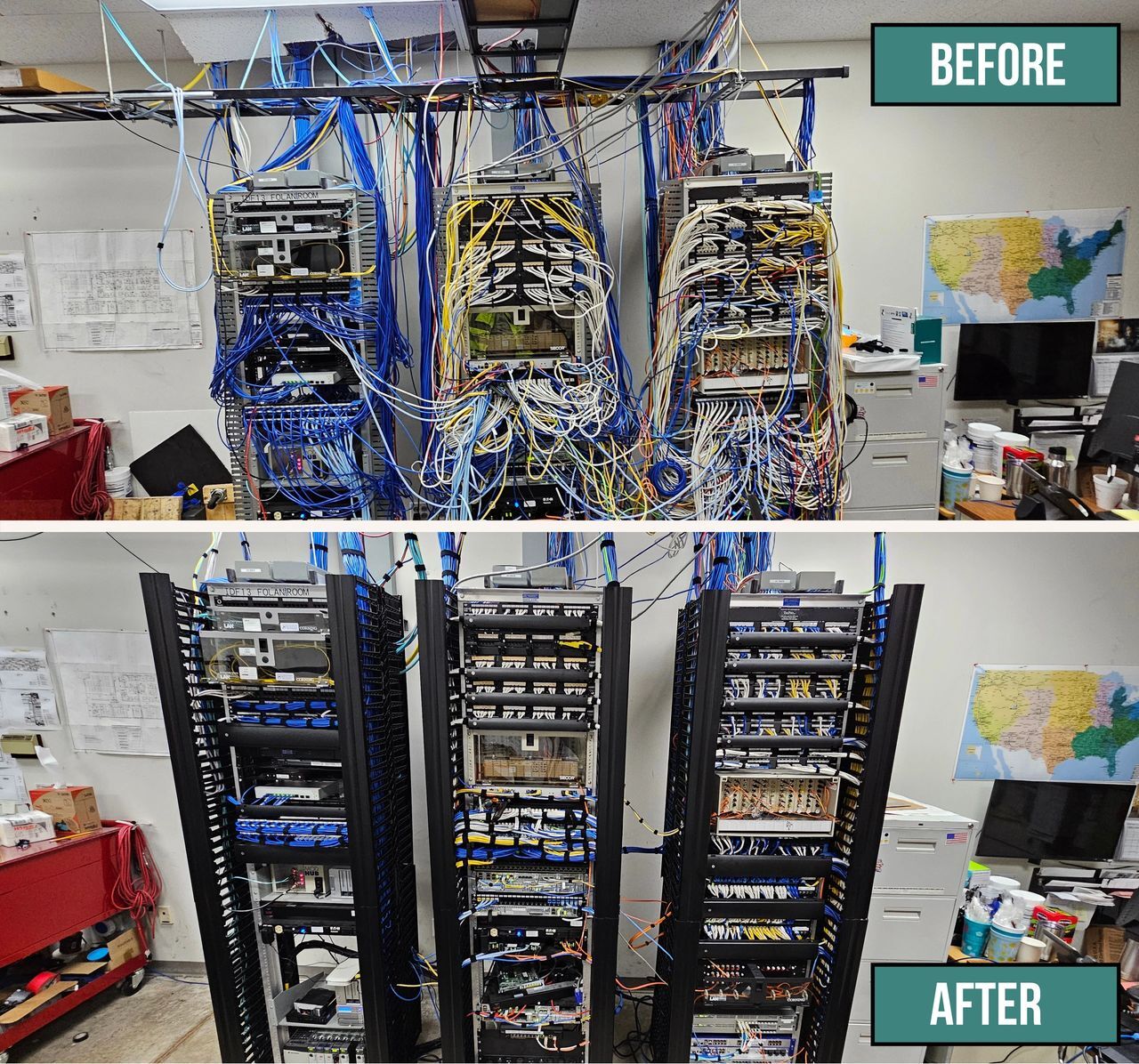

Before: Disorganized cabling and unstructured switch layout — After: Vertical management added, cables bundled, labeled, and the spaghetti mess transformed into a clean, efficient network core.

Diving Deep: Our Initial Diagnosis & Strategic Planning

Orion US’s in-depth site review went beyond simply pinpointing issues; it focused on uncovering the underlying causes of the tangled cabling situation. Our team swiftly identified three top-priority areas within IDFs. Each of these zones presented distinct challenges, requiring a customized, structured cabling approach tailored to their specific complexities. Each of these IDFs were:

- Tucked away in a utility breaker room, was a lesson in constrained space. Its compact footprint, coupled with loosely managed fiber runs, cried out for ultra-efficient space utilization and an impeccably clean, safe cable organization.

- Precariously positioned above the bustling production floor, was bursting at its seams. Extreme cable congestion, frustrating accessibility issues, and constant environmental exposure made a full relocation behind the existing wall an absolute necessity.

- Within the office tech room, housed four racks packed with legacy patch cords, mixed Cat6/Cat6A runs, and unorganized vertical routes. Maintenance teams struggled to trace connections without risking downtime.

To effectively manage this complex redesign, Orion US’s engineering team undertook a thorough port mapping process. Each copper and fiber connection was carefully identified, recorded, and verified prior to starting the migration. Our recommendations were both targeted and transformative:

- Relocate IDF into a robust 42U NEMA 12 standing cabinet, engineered to defy industrial environmental challenges.

- Install dedicated cable ladders and fiber runners to forge crystal-clear routing pathways, banishing tangles forever.

- Deploy enterprise-grade Commscope Systimax Cat6A cabling and Corning SM fiber – ensuring a high-performance, resilient backbone that would stand the test of time.

- Integrate universal vertical and horizontal cable management systems to bring enduring structure and effortless scalability to each IDF.

New Rack for IDF; IT and OT Wireless services inside, less dusty and better supportable area

Every single decision, every strategic move, stemmed from one unwavering principle: designing for longevity and serviceability, not just a temporary fix. This was about building an enterprise network upgrade that would last.

From Scratches to Solutions: The Design & Problem-Solving Journey

The earliest planning sessions endearingly dubbed the “chicken scratch” phase—were where Orion US’s technical creativity truly came to light. Amid these open-ended sketches and energetic discussions, we tackled the facility’s biggest challenge head-on: executing a complete network transformation within a strict 12-hour maintenance window, all while production ran non-stop. In these circumstances, precision planning wasn’t just beneficial; it was imperative.

Our expert engineers meticulously crafted a phased migration plan, designed to surgically address each IDF with minimal impact:

- Phase 1: Focus entirely on migrating and rigorously testing

- Phase 2: Execute a complete rewiring and cleanup

- Phase 3: Finalize all cable management and labeling

This strategic, phased approach drastically slashed downtime risks, allowing critical production systems to hum along uninterrupted between each transition. To further accelerate deployment, our team ingeniously devised a plan to pre-stage complex equipment off-site, ensuring rapid, seamless integration once on location.

Specialized considerations were paramount, especially for fiber routing through tough industrial walls. This required a new 4-inch core alignment, perfectly integrated with the existing cable path for the relocated IDF. The result was an exceptionally clean, highly accessible layout that not only optimized crucial airflow but utterly eliminated hazardous cable cross-pathing.

The Art of Installation: Precision in Every Connection

With the strategic blueprint firmly in place, execution began with a symphony of synchronized timing and an unyielding focus on safety. Over multiple, carefully managed phases, the dedicated team:

- Installed cutting-edge ladder racks, vertical managers, and horizontal troughs, meticulously designed to separate and route cables with unparalleled efficiency and order.

- Systematically removed outdated, problematic patch cords and standardized all terminations using pristine Cat6A blue cabling, creating consistent visual appeal and flawless functional uniformity.

- Successfully relocated IDF into its brand-new industrial-grade cabinet, now boasting robust dust and moisture protection.

- Labeled, tested, and comprehensively documented every single port and patch, guaranteeing effortless future serviceability and rapid fault isolation.

Beyond Connectivity: The Lasting Impact for Facility

For the facility, Orion US’s intervention delivered lasting value that extended far beyond surface-level improvements. The newly installed structured cabling solutions offered:

- Simplified maintenance and rapid fault isolation: A direct result of crystal-clear labeling and comprehensive documentation, cutting down troubleshooting time dramatically.

- Significantly reduced downtime risk: Offering invaluable peace of mind during any future upgrades or necessary expansions.

- Improved airflow and enhanced safety: Achieved through perfectly organized routing and the elimination of hazardous cable clutter.

- Unrivaled future scalability: The robust infrastructure is now primed to effortlessly support next-generation smart manufacturing technologies and critical IoT integration.

Conclusion: Structure that Sustains Production

What began as a disorganized tangle of patch cords evolved into a showcase of structured efficiency and reliability.

Through meticulous planning, disciplined execution, and precise craftsmanship, Orion US delivered a wired infrastructure that now powers the client’s demanding production environment with security, clarity, and confidence.

When your facility’s IDFs start showing the strain of time and patchwork upgrades, choose a partner who doesn’t just “pull cables,” but engineers lasting network order.

Please get in touch with the experts at Orion US today.

Image Source: Canva